Industry News

Home > News > Industry News... > Five Essentials For ...

CONTACT US

- Tel: 0086 15961653782

- Email: info@brightsail-asia.com

- Address: No.291 Nan Street,Zhutang town,Jiangyin City,Jiangsu Province,China.

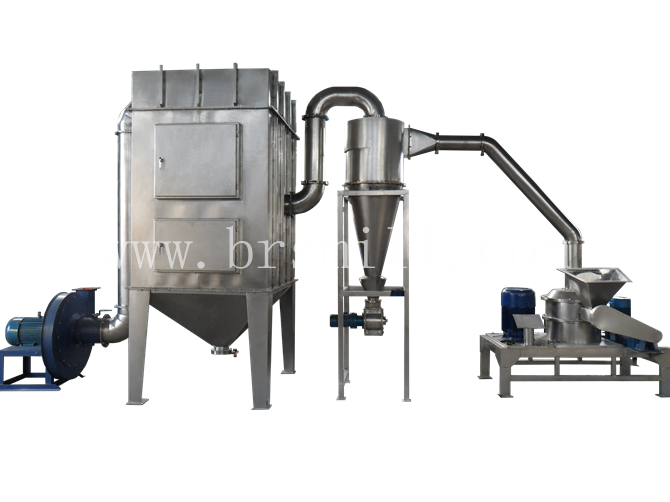

Five Essentials For The Detection Of Air Classifier Mill

Source:

Date: 2018.09.17

Clicks:

Any equipment needs to undergo a series of rigorous tests before it can be put into use. How to make the ACM Grinder do the correct detection?

1. Newly installed equipment, when the equipment is in place and the warehouse to be pulverized, it will inevitably leave foreign matter such as iron, electrode head and welding slag. In the case of not opening the fan and the main motor, open the deblocking baffle under the inlet to allow impurities and washing materials to be discharged from there.

2. When Fine Powder Grinder Supplier check everything in the early stage, power on the device. Check the direction of rotation of all motors.

3. Check whether the solenoid valve is blown normally or not, and adjust the pulse width of the solenoid valve of the dust collector and the interval between injections.

4. Check if there is any air leakage in the airlock below the brake cylinder. You can put the hand or fine powder on the interface to feel the suction. If necessary, seal it. After the above inspections are all normal, the materials are prepared for production.

5. Perform parameter check on the two inverters of the feeding motor and the classifying wheel motor of the superfine pulverizer. Check whether the air conditioner, contactor, thermal relay and overcurrent relay corresponding to the motor are suitable for adjustment. Relock it again.